I started off Thursday morning visiting one of Winnipeg’s most famous tourist attractions: The Royal Canadian Mint. Located on the outskirts of Winnipeg’s city centre, the mint is where all of Canada’s circulation coins have been made since 1976. However, the mint doesn’t just make Canada’s circulation coins, it also makes the circulation coins for 75 countries around the world!

While I figured the mint would be interesting in a “oh hey, that’s kinda neat” kind of way, I didn’t realize how enjoyable and fascinating my visit would be. I loved it! My first word of advice if you’re going to visit: pay for a guided tour. There is no comparison otherwise.

I was fortunate enough to have my own private tour with Justin, a chemistry student who’s been working for the mint for the past three summers. His goal is to become a science teacher, and I know he’ll make an excellent one at that.

We took the escalator up to the second floor and through the areas where you can look down from above and see the workers and machinery – an area where nobody is permitted to take pictures due to security reasons, of course.

Justin took me from room to room, explaining every step of the coin-making process, keeping me engaged and guessing the entire time. He took items we take for granted (quarters, loonies, toonies, nickels, dimes) and revealed the hidden secrets behind their existence. You think you know how a coin is made? Nah, its not as simple (or as boring) as you think.

The facts were also cool to learn. For example, the Royal Canadian Mint 20 million coins per day. And since 2001, Canadian circulation coins have been made using a steel core. And did you know that there were the same amount of toonies made in 1996 than they were between 1997 and 2013? Today if you pull out a toonie from your pocket, there’s a 50% chance it’s from 1996. And yes, if you’re ambitious and crafty, you can pop the centre out of the 1996 toonies. But we wouldn’t do that now, would we?

But back to the tour. The Royal Canadian Mint makes our coins in 7 steps.

1. Blanking. This is where a machine punches the round coin shapes out of the steel sheets, creating blanks. The shape and thickness of the blanks vary depending on the coin being made. Dimes are thinner than nickels. Canadian coins are round, Hong Kong coins are flower-shaped, and so on.

2. Rimming. This is where pressure is applied to the steel blanks to create an elevated rim. Justin made me guess why the rim even exists, and to be honest, I never thought about it before. Turns out it’s to protect the image on the coin when the coin comes in contact with a flat surface. Cool, huh?

3. Plating. Justin said is the most important process. The Royal Canadian Mint uses an innovative patented process where they plate each coin with a microscopic layer of nickel, then copper and nickel, and together it’s about 1/10th the thickness of a piece of paper. It takes 28 containers and 8 hours to complete this process, and since it’s cyanide-free (unlike conventional plating processes), it’s environmentally-friendly.

4. Annealing. I didn’t know this word, either. Well this step involves heating the coin in 500 degrees Celsius for 20 minutes. Liked to a sauna, it softens the metal so that they’re no longer stressed, and they’re more malleable so that less pressure can be applied in the later coining step.

5. Burnishing. Think of a rock tumbler. Sulphuric acid and metal beads are used to polish the coins clean. This step takes 30 minutes to complete. They come out looking shiny and new.

6. Coining. The coins are effectively stamped with a “die” that contains the image that will appear on the coin. 200 tonnes (!) of pressure is used in this step, and a ring is also placed around the coin to give it its serrated edges. (Can you guess how many edges a loonie has?)

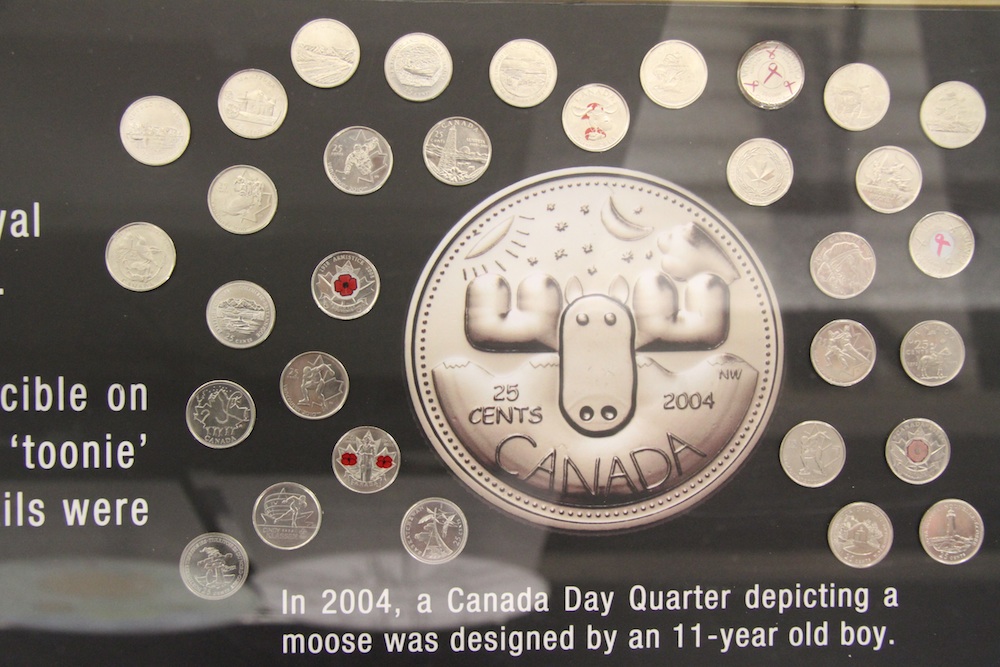

Die production is separate step entirely, which also involves creating the design for the coin, and transferring the image onto said die. And anyone can submit an image to be considered for a coin, did you know that? I didn’t. But that makes sense. And every artist who designs a coin has their initials on there somewhere. Just look at your pocket change for proof. It’s like a spontaneous Where’s Waldo every time!

But what’s insane about the coining step is that the Royal Canadian Mint uses a machine that does this process 6 coins a second, and also 14 coins a second. The mint stays open 16 hours a day, Monday to Friday. You do the math.

7. Packaging. Canada apparently likes its coins in plastic rolls. Barbados likes its coins in big plastic bags. Other countries prefer paper rolls. Each country and coin type has its own set packaging preferences, and the Royal Canadian Mint must accommodate. Once packaged, they’re placed in a vault and then off they go, into randomly-marked trucks across Canada, or to the ports, and then shipped off to whatever country they’ll be used.

After my tour, Justin and I headed back down and explored the gift shop. There were also some fun hands-on exhibits and displays, like the old coining machines used back in the olden days. There was also a pool where you could make a wish, and toss a coin. Justin said you can think of it like bringing the coins back to where they originated.

The 2010 Olympic and Paralympic medals were on display, and seeing them was like seeing an old lost friend I hadn’t seen in three years.

There was also a gold bar, guarded with an armed security officer.

The goal is to try to lift up, and then you realize how heavy it is, and then they tell you the price, and you start sweating at how expensive it is.

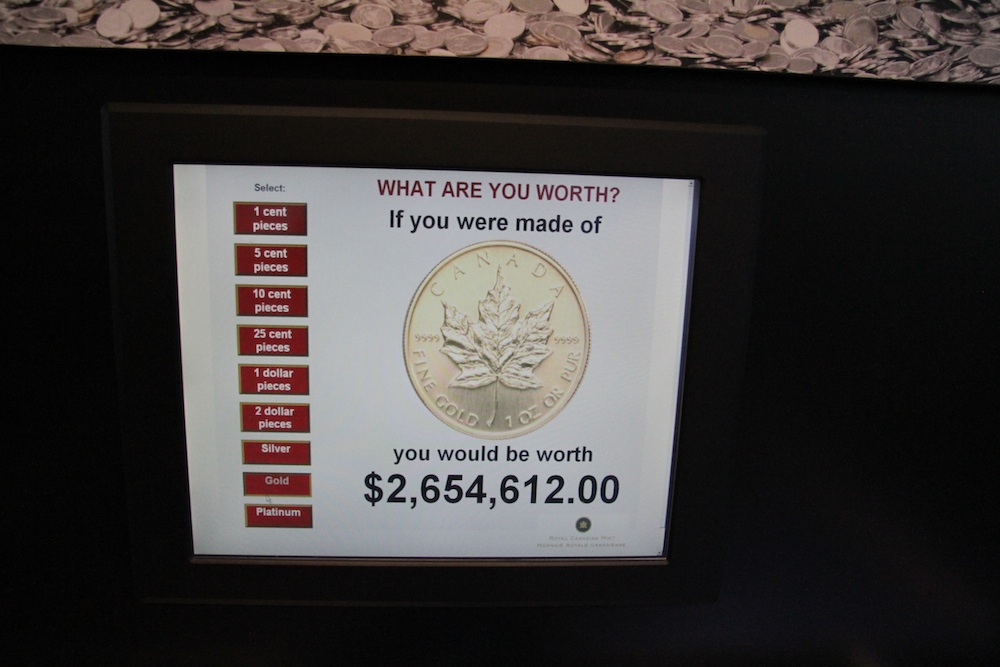

Another fun activity included the scale where you could weigh yourself and it would tell you how much you’d be worth if you were made out of gold (or silver, or…).

And there was also an interactive map displaying all the different countries that get their circulation coins made in Canada. I had no idea the USA made their coins in Canada. Who knew?

Leaving the Royal Canadian Mint, a bunch of landscapers who were working outside asked me if it was worth visiting. “Absolutely!” I said. “Make sure you take the tour”.

After seeing where money was made, I was off to my next logical stop in Winnipeg: the casino!